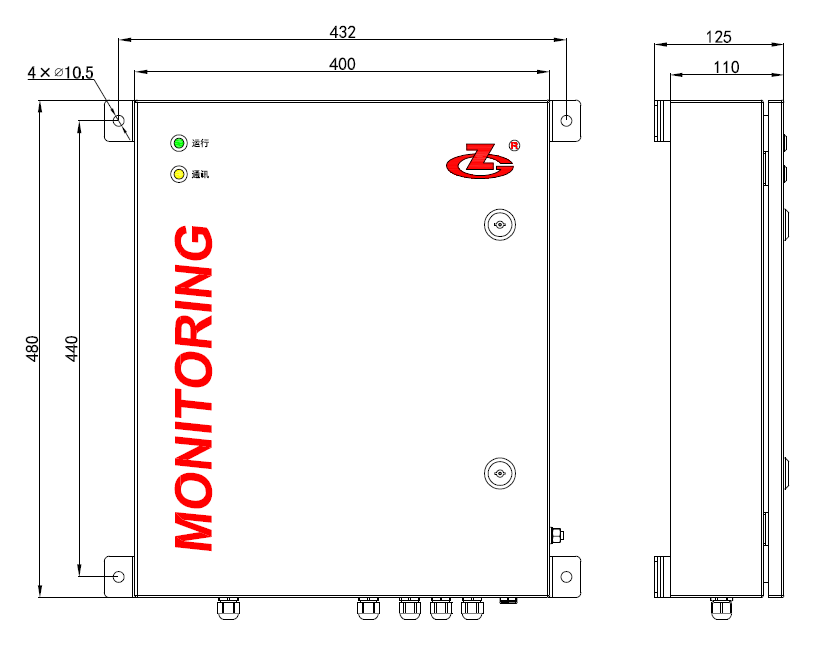

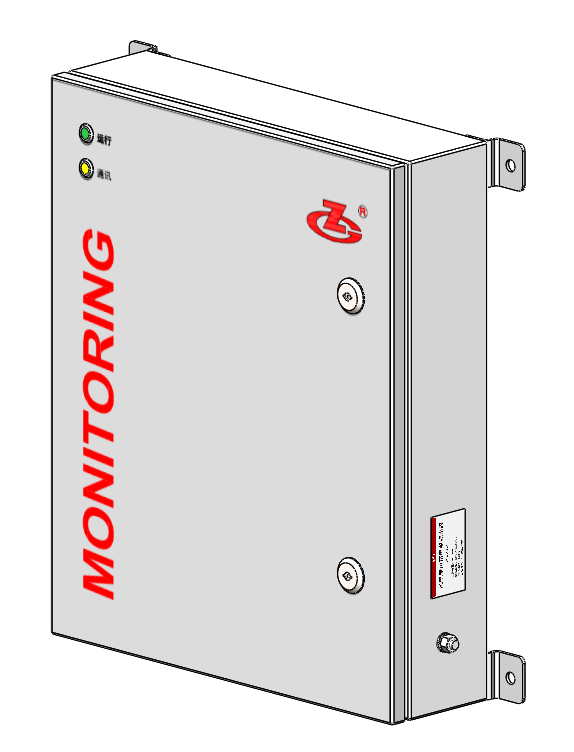

ZGLJ-B3 Multi-channel Lightning Monitor of the Wind Power System

General

The system can monitor the lightning current information of wind turbine blades subjected to lightning strikes in real time and accurately.

The system consists of the lightning current sensor installed in the blades and hubs, lightning monitor, and lightning data management software for the monitoring center.

Operating Environment

| Power supply |

AC: +230 V |

| Temperature |

-40 ℃~70 ℃ |

| Relative humidity |

5 %~100 % |

| Atmospheric pressure and altitude |

62 kPa~106 kPa, 4000 m~-500 m |

Product Configuration (Standard Configuration)

| Name |

Quantity |

Unit |

Remarks |

| ZGLJ-B3 lightning monitor |

1 |

PCS |

|

| Lightning current sensor |

3 |

PCS |

|

| Lightning data management software |

1 |

Set |

For one project, a set of software programs is equipped. |

Performance Index

| Item |

Index |

| Monitored object |

Lightning occurrence time, peak value, polarity, number of times, charge amount, specific energy, and steep-wave coefficient |

| Monitoring range of lightning peaks |

±5 kA~±250 kA |

| Measuring error |

≤±100 kA: ≤±10 % |

| >±100 kA: ≤± 5% |

| Error in the front time and time to half value |

≤±10% |

| Sensor frequency response |

1Hz~1 MHz |

| Sampling frequency |

10 MHz |

| Waveform acquisition length |

1 s |

| Storage capacity |

≥8 GB |

| Communication interface |

RS485/CAN/Ethernet/Wi-Fi |

| Communication protocol |

Profibus DP/CANOPEN/Modbus TCP |

| Waterproofing grade |

IP65 |

| Overall power consumption |

≤12 W |

| Weight |

≤15 kg |

Standards Complied

Q/75875187-9·7 - 2016 Lightning monitoring system

GB/T 3783-2008 General specification for low-voltage apparatus in ships

GB/T 3797-2016 Electrical control assemblies

Configuration

Working Principle

As the highest-position component in a wind turbine, the blade is the primary target of lightning strikes, and also is the most expensive component of the wind turbine, so the lightning protection is critical. In most cases, the location of the lightning strike is on the back of the blade tip. Currently, most of the blades are equipped with a special lightning protection system, which consists of a lightning receptor and a lightning conduction part. Inside the blade, the lightning conduction part directs lightning from the lightning receptor into the metal flange at the root of the blade and through the hub to the engine room. The protection of the gap discharge at the flange of the hub rapidly transmits the lightning current to the base of the engine room and releases the lightning overvoltage.

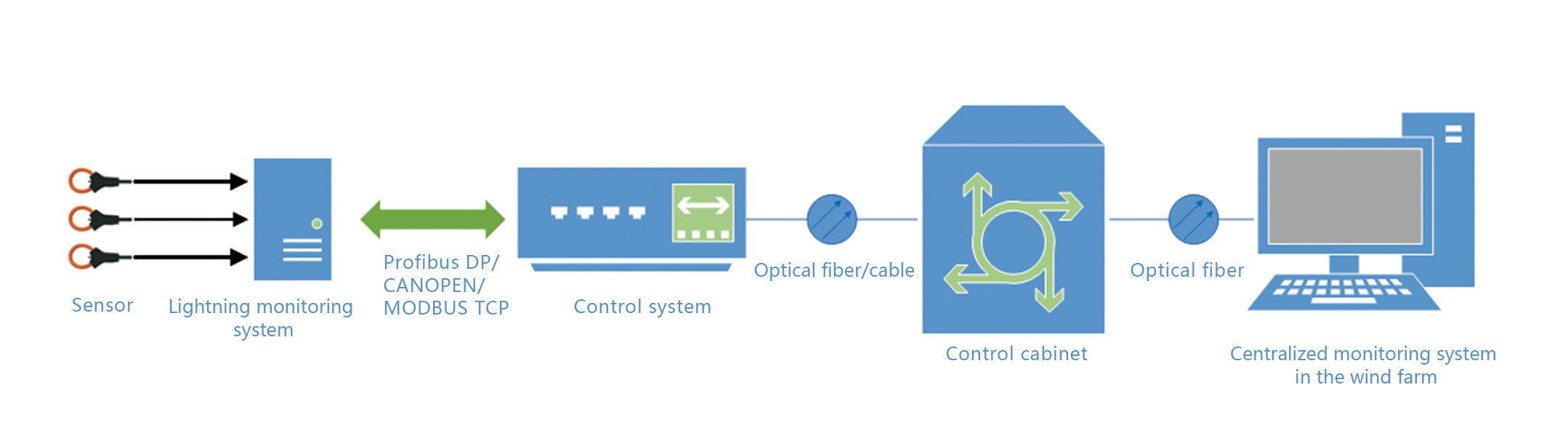

The lightning monitoring system can accurately sense the lightning current signal of the wind turbine blade subjected to lightning strike in real time and send it to the lightning monitor through the lightning current sensor installed in the fan blade. The lightning monitor will collect, calculate, and record the lightning strike time, lightning current peak, polarity, charge amount, specific energy, and steep-wave coefficient and store them in the internal memory.

The lightning monitoring system has RS485/CAN/Ethernet/Wi-Fi communication interface, and executes Profibus DP/CANOPEN/Modbus TCP. The monitored data is transmitted to the control system in the engine room through the interface, and to the control box of the tower base through the control system, and then to the monitoring center from the control box, to realize data display, management, statistics, and reporting through the centralized monitoring system of the wind farm.

Functional Characteristics

4.1Real-time monitoring of lightning strike failures

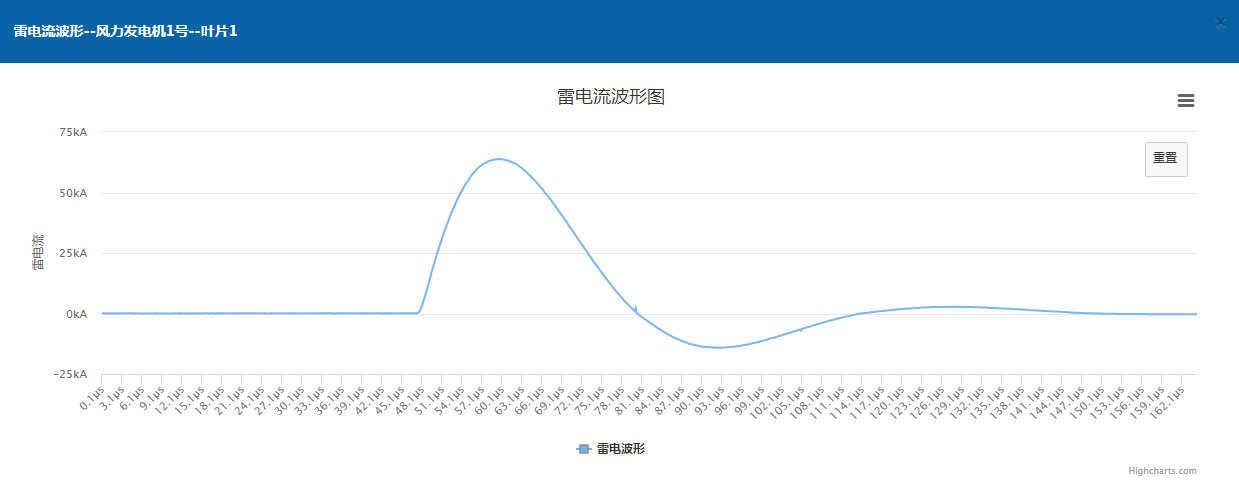

Real-time recording of lightning strike time, peak lightning current, polarity, charge amount, specific energy, and steep-wave coefficient.

Large-capacity data storage

The internal storage capacity is up to 8G and the waveform records can reach up to 300.

With data save in case of power failure, long-term monitoring can be realized to avoid data loss.

High-precision sensing technology

The non-contact high-precision transient current sensor is used for wide-band signal response, which can effectively sense the lightning signal.

Dual power supply

External DC power supply + built-in lithium battery power supply, monitored data can be recorded and transmitted in the case of external power interruption.

High reliability

The requirements of GB/T 3783 are met, with strong anti-interference ability;

Built-in hardware watchdog circuit, so crash is never going to happen;

The structure design process is exquisite and light in weight. With the multi-layer isolation and watertight materials, it is resistant to high temperature, shock, aging, corrosion and salt spray, and has the characteristics of maintaining normal function in harsh environment.

Data statistics and analysis

Lightning data management software can realize the storage, analysis, and statistics of lightning data of the wind turbine; the effectiveness of lightning protection facilities is evaluated, to provide a basis for lightning protection design and reconstruction in the area.

Lightning Management Software

The lightning data management software is a kind of management software specially developed for the functions of lightning monitoring system setting, data downloading, management, reporting, printing, etc. It can support the digitization and paperless management, analysis and processing of lightning monitoring information.

The lightning data management software displays the distribution trend of time and density of lightning damage on the wind turbine in various ways such as data, graphs and tables, and realizes real-time monitoring of the lightning damage condition of the wind turbine within the monitoring range. Macroscopic statistics on the lightning strikes of wind farms, and analysis and judgment of the lightning damage conditions of wind turbines can be convenient for evaluation of the effects of lightning protection facilities for wind turbines, providing a basis for the lightning protection design, reconstruction and insurance claims in the area, to ensure the safe operation of wind turbines.